Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

82mmResolução

0.1um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

82mmResolução

0.1um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

82mmResolução

0.1um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

82mmResolução

0.1um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

3+L/200Repetibilidade

3umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/100Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/100Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/100Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/100Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.5um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

18~195XCampo de visão

8.1~1.3mmDistância de trabalho

82mmResolução

0.1um

Precisão

2.5+L/200Repetibilidade

2.5umAmpliação de vídeo

25.2~158.4XCampo de visão

8.1~1.3mmDistância de trabalho

90mmResolução

0.1um

Precisão

Repetibilidade

Ampliação de vídeo

Campo de visão

Distância de trabalho

Resolução

Precisão

Repetibilidade

Ampliação de vídeo

Campo de visão

Distância de trabalho

Resolução

ÚLTIMAS NOVIDADES

TIME:12-25 2020

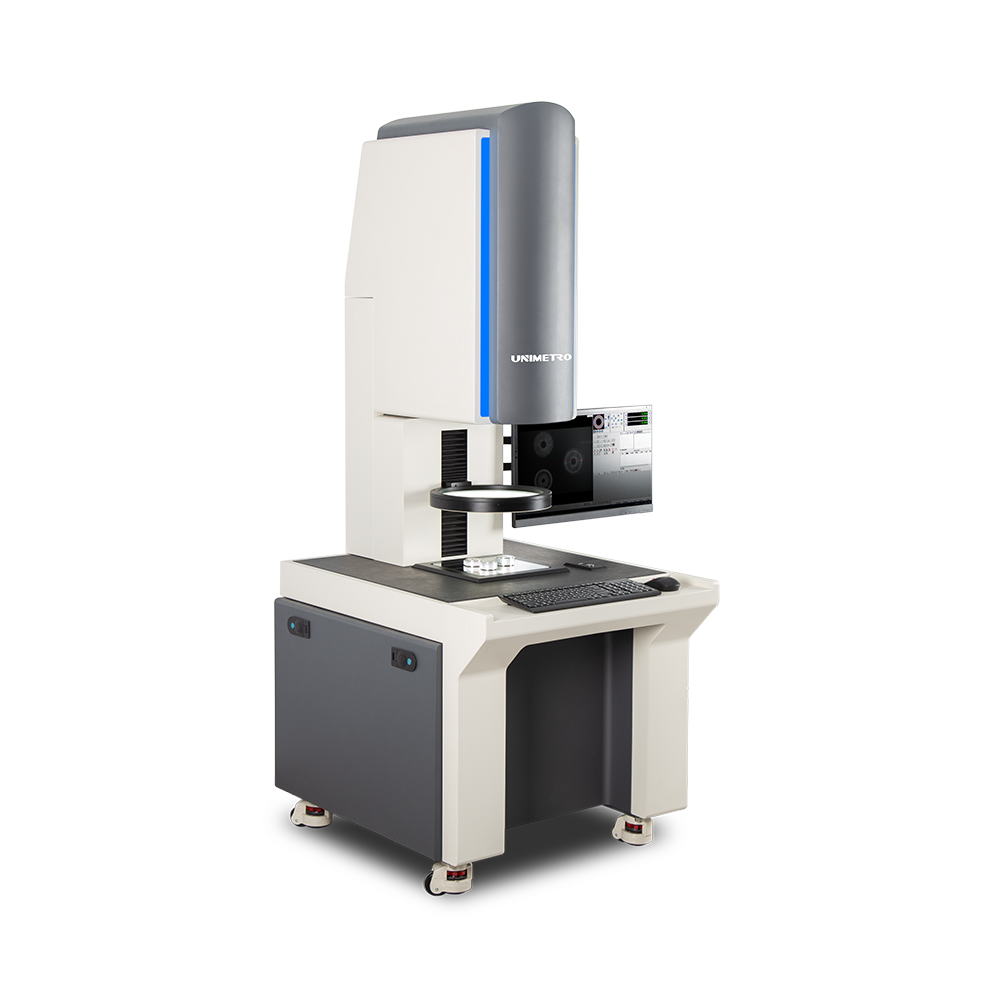

The full-automatic image measuring instrument has three modes: CNC scanning measurement, manual measurement and automatic memory measurement, and can stack the modules of the three modes for composite measurement. By scanning the generated image, the full screen target traction is realized. The graphics generated from the measurement results are synchronized with the image map. It can click the graphics to automatically return to the original position and enlarge the full screen eagle eye. It can correct the imaging error of any measured size through the measurement of standard parts, and calibrate it, so as to further improve the batch measurement Precisão of key data.

The software of CNC automatic image measuring instrument has memory function. The first detection is completed by manual operation, and the whole detection process will be recorded by software, which can be used as reference for automatic detection in the future. The user does not need to write any other program.

Automatic image measuring instrument is the advanced stage of image measuring technology, which has the characteristics of high intelligence and automation. Its excellent software and hardware performance makes the coordinate measurement convenient and comfortable. It has the automatic learning function based on machine vision and process control. Relying on the high-speed and accurate micron level movement of digital instruments, it can self-study and memorize the measurement process path, focusing, point selection, function switching, manual correction, light matching and other operation processes. The full-automatic image measuring instrument can easily learn all the practical operation processes of the operator, and realize artificial intelligence by combining the fuzzy operation of automatic focusing and area search, target locking, edge extraction and point matching. It can automatically correct the offset caused by workpiece difference and position difference, and realize accurate point selection with high precision and Repetibilidade. Thus, the operators can be freed from the monotonous operations such as fatigue accurate visual alignment, frequent point selection, repeated movement and function switching, and the increasingly heavy tasks to be tested, and the batch testing efficiency of workpieces can be improved hundreds of times to meet the needs of industrial sampling and mass testing.

It integrates CNC rapid measurement, CAD reverse mapping and image management. Using modern optics, computer screen measurement, space geometry operation and precise motion control and other cutting-edge technologies, it is a highly intelligent equipment integrating optics, machinery, electricity and software. It has the basic functions of three-axis numerical control, point to go, image and shadow synchronization, real-time calibration, error correction, workpiece random placement, CNC rapid measurement and so on.

+55 11 4942 2222

Whatsapp:+55 11 9641 6776

TEL:+55 11 4942 2222/2220

E-MAIL:vendas@enterfix.com.br

-

PRODUTOS

-

SOLUÇÕES

-

VIDEOS

-

ÚLTIMAS NOVIDADES

-

SOBRE NÓS